Zero leak-by control valve eliminates first wafer effect.

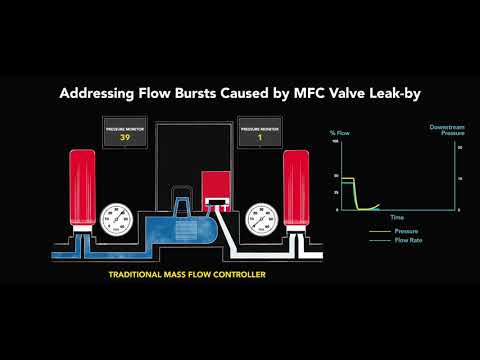

When a gas leak-by occurs across the MFC control valve, it causes unwanted pressure build-up at the downstream pneumatic isolation valve, resulting in the formation of a trapped volume of gas.

When a new recipe sequence is initiated, this trapped volume of gas goes into the process chamber, causing non-uniformities and Critical Dimension (CD) defects on the first wafer, known as first wafer effect. Process engineers avoid the first wafer effect by either running a dummy wafer or diverting the flow into exhaust prior to processing the wafers.

An optional zero leak-by control valve with an engineered PCTFE sealing surface delivers improved valve shutdown to eliminate first wafer effects:

- <0.005% FS for bins 42-46

- <0.02% FS for bins 40-41